Analysis of the Causes of Acid Corrosion and Prevention Measures in the Recovery Process of Acidic Condensate from the Condenser Preheater

The emergence of condensing boilers has significantly enhanced the thermal efficiency of gas boilers and the effective

utilization of natural gas. The exhaust temperature of such boilers is typically below 50℃, so the water generated from

burning natural gas often exists in liquid form, commonly referred to as condensate.

Strategies for handling condensate:

Condensate not only contains water molecules but also a large amount of pollutants generated from combustion, such

as nitrogen oxides and sulfur oxides, which dissolve in the condensate. If these substances reflux into the chimney, they

can cause severe corrosion to the chimney walls, reducing the lifespan of the boiler.

Therefore, in practical operation, to prevent the corrosion of condensing boilers by condensate, it is necessary to

discharge the condensate from the boiler body. If this condensate is discharged into the environment without

treatment, it will cause serious environmental damage and waste of resources. So, how should we handle this condensate?

The acids and metal ions in condensate can have adverse effects on the environment. Therefore, when selecting a

treatment system, it is essential to carefully choose the material of the condensing heat exchanger and adjust the

Total Quality (TQ) to neutralize acidity, thereby reducing the concentration of metal ions.

The methods for treating condensate mainly include the following:

1. Dilution method: Diluting the acidic condensate with tap water to adjust its pH value. However, this method leads to

water resource wastage, and the corrosiveness of condensate with a pH value around 3 is still strong during the dilution

process.

2. Material neutralization method: Neutralization treatment is the most effective method for condensate treatment, which

involves two processes: neutralizing acids and adsorbing heavy metals. This method provides a specialized condensate

neutralization system, where the condensate is neutralized by alkaline substances to achieve neutralization of the

condensate.

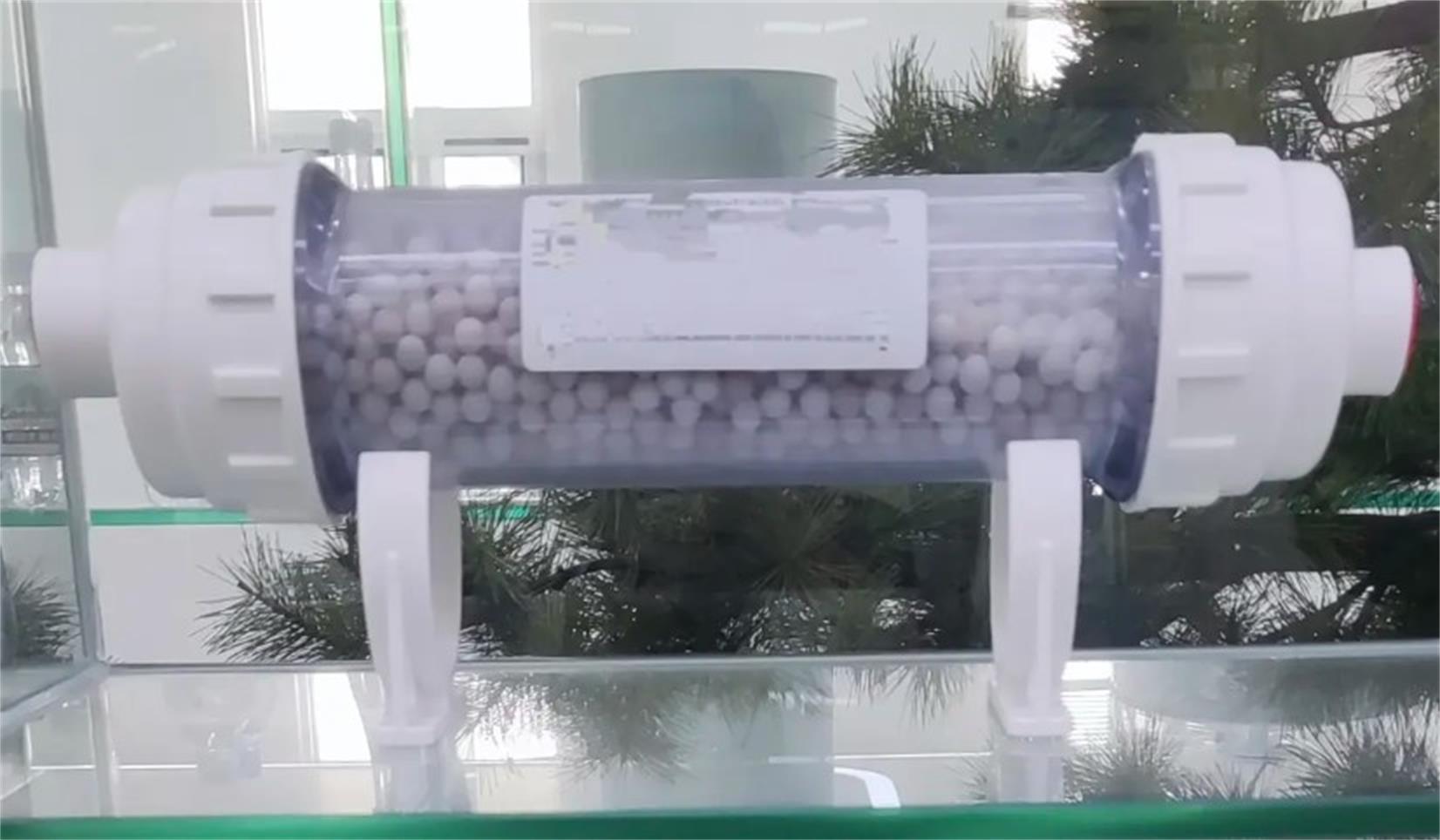

To neutralize acidic condensate, Shandong ETERNAL WORLD has introduced a new type of condensate neutralization

equipment material - condensate neutralization balls. This material is composed of pure natural inorganic minerals and

is formed into ceramic beads through granulation, possessing the following advantages:

1. Safety and environmental protection: It does not contain toxic or harmful substances, thus avoiding secondary

pollution to water bodies.

2. Long service life: It is resistant to wear and dissolution, allowing for control of the pH value of the water after

neutralization.

3. High hardness: It does not produce precipitates or scaling, maintaining the smoothness and efficiency of the

4. Strong functionality: It not only effectively raises the pH value of the condensate but also adsorbs harmful

substances such as heavy metal ions, improving the water quality of the condensate.

By simply adding a set of equipment containing condensate neutralization balls at the end of the condensate

discharge, dynamic adjustment of pH can be achieved, realizing the discharge of neutral water, and preventing

the corrosion of pipes and machinery by acidic condensate. The figure below shows an overseas condensing boiler

application with a neutralizer.