How can water purifiers and commercial water purifiers be upgraded to hydrogen ion mineralized water machines through mineral hydrogen-producing materials (hydrogen ion balls)?

After more than 20 years of development, the demand for traditional water purification functions has become saturated.

Like smartphones and home appliances, water purifiers also need to be updated and continuously innovated to meet

the needs of users in the new era. Only through functional upgrades can water purifiers gain new market opportunities

and break through the predicament.

1. Hydrogen ion water is a highly promising functional health water:

Hydrogen is a secondary energy source with abundant sources, green and low carbon, and wide-ranging applications,

gradually becoming one of the important carriers for global energy transformation and development. China has

basically formed an industrial chain for the preparation, storage, transportation, and application of hydrogen.

The hydrogen energy industry has gradually formed two huge trillion-dollar market scales: hydrogen energy and

hydrogen biology.

In addition to its application in the energy industry, hydrogen has also achieved good results in multiple industries

such as health, medicine, and agriculture. Since Japanese researchers discovered in 2007 that trace amounts of

hydrogen gas (at ppb levels) can produce positive biological effects on organisms, scientists worldwide have been

conducting extensive research on the application of hydrogen gas in animals and plants, and have achieved

encouraging results. As research on the application of hydrogen gas in medicine, health, and agriculture has

gradually deepened, a new field called the hydrogen biology industry has emerged.

Hydrogen ion water has become a new favorite among functional waters due to its safety, effectiveness, and

characteristics such as antioxidant and anti-inflammatory properties. After more than 10 years of development,

the hydrogen biology health industry has begun to take shape. The United States, Japan, and China are the countries

with the most research on the medical and biological effects of hydrogen gas, with renowned research institutions

such as Harvard University, Tokyo Medical University, and Peking Union Medical College actively participating in research.

Academic institutions in Hungary, Germany, South Korea, and other countries have also been actively involved in such

research. Thousands of researchers from around the world have jointly published more than 1,600 papers on hydrogen

molecule biology. As of 2020, more than 90 projects funded by the National Natural Science Foundation of China have

been related to the biological effects of hydrogen gas. Many medical institutions including the Naval Medical University,

Tianjin Medical University, Shandong First Medical University, Beijing University of Technology, Shanghai Jiao Tong

University, Xi'an Jiao Tong University, Peking University, Air Force Medical University, Army Medical University, Guangzhou

Medical University, Chinese Academy of Medical Sciences, Harbin Medical University, China Medical University,

Qingdao University, Shenzhen University, and the General Hospital of the Chinese People's Liberation Army have

conducted dozens of studies on hydrogen gas medicine, covering a wide range of diseases including chronic obstructive

pulmonary disease (COPD), diabetes, metabolic syndrome, Parkinson's disease, cancer adjuvant therapy, hepatitis B,

angina, and other important diseases in both basic and clinical research.

In 2020, the China National Medical Products Administration approved hydrogen-oxygen atomization inhalation as a

Class III medical device for treating acute exacerbations of COPD. In the seventh and eighth editions of

the "Diagnosis and Treatment Plan for COVID-19 Pneumonia" issued by the government, hydrogen inhalation is also

recommended as a treatment method. This signifies the Chinese government's most important recognition of hydrogen

therapy.

Currently, the hydrogen health industry has become a new emerging health industry with a market size of billions.

There is a wide variety of hydrogen products including hydrogen-rich cups, hydrogen inhalers, hydrogen water machines,

hydrogen masks, and more.

Drinking hydrogen-rich water has become a new consumer trend, benefiting more and more people. Hydrogen water

machines, as terminal equipment for producing hydrogen ion water, are increasingly favored by consumers for their

versatility in drinking, cooking, washing vegetables, and other purposes. With the development of the hydrogen health

industry, the popularity of hydrogen water machines has provided a good path for upgrading the functionality of water

purifiers and overcoming difficulties.

2. Comparison of two technologies for preparing hydrogen-rich water using hydrogen water machines:

Currently, many water purifier manufacturers have begun to transition to introduce hydrogen water machines or add

hydrogen water production functions. This not only enhances the functionality and value of water purifiers but also injects

new vitality into the market. Hydrogen water machines, including household and commercial ones, generally adopt PEM

electrolysis or mineral hydrogen-producing technology.

There are mainly two types of electrolytic hydrogen production technologies: alkaline water electrolysis and PEM

(Proton Exchange Membrane) pure water electrolysis. Currently, PEM pure water electrolysis has become the mainstream

technology for hydrogen production equipment. It has relatively low internal resistance and produces relatively pure

hydrogen gas, making it a key development focus for future hydrogen production technologies. PEM pure water electrolysis

hydrogen production technology, with its high efficiency and sustainability, is one of the hydrogen production technologies

adopted by hydrogen water machines. However, PEM electrolysis hydrogen water has significant drawbacks, including high

manufacturing and maintenance costs, resulting in a high market price. Additionally, its durable nature and qualification

issues limit its large-scale development and make it difficult to popularize in the market. This is also the main reason why

electrolytic hydrogen water machines, although introduced early, have not yet become widespread among households.

Mineral hydrogen production technology originates from the natural background of hydrogen water production from

Nordenau rock minerals in Germany. It uses a combination of mineral hydrogen-producing materials and ceramic

materials to simulate the principle of rock mineral hydrogen production. Compared to electrolytic hydrogen production

technology, it is characterized by easy use, low cost, maintenance-free operation, and high-frequency consumption.

Additionally, mineral hydrogen production technology can also achieve the characteristics of weak alkalinity and small

molecular cluster water, which better meet the needs of the Chinese people. This is also why mineral hydrogen production

technology is becoming the mainstream factor for upgrading the functionality of water purifiers.

| Advantages and disadvantages of PEM electrolysis water hydrogen production and mineral hydrogen production technology | |||

| Hydrogen production technology | Hydrogen production characteristics | Price/Cost | After-sales service |

| PEM electrolysis hydrogen production | Continuous and efficient | High price/High cost | Damaged electrolyzer/high replacement cost |

| Hydrogen production from mineral materials | Efficient | Low price/Low cost | Regular replacement of filter element/secondary profit |

3. Implementation and Selection of Hydrogen-rich Technology of Mineral Hydrogen Production Materials

Water purifiers typically employ purification technologies such as ultrafiltration, nanofiltration, and reverse osmosis to purify water into clean or pure water. In contrast, mineral hydrogen water machines achieve hydrogen water production by installing mineral hydrogen-producing filter cartridges after the purification filter cartridges in traditional water purifier processes. This method is characterized by its simplicity and low cost. Depending on the actual needs of different users, household water purifiers require 2-3 kilograms of mineral hydrogen production materials, while commercial water purifiers require 8-10 kilograms. This can achieve a hydrogen water content of over 1000 ppb and a lifespan of up to 10 months.

4. Things to note when choosing mineral hydrogen production materials

4. Things to note when choosing mineral hydrogen production materials

Firstly, it is essential to conduct factory audits of manufacturers. Through these audits, the production process and quality control of mineral hydrogen production materials can be evaluated. This helps ensure that the selected materials comply with relevant quality standards and regulatory requirements, thereby ensuring their performance and safety.

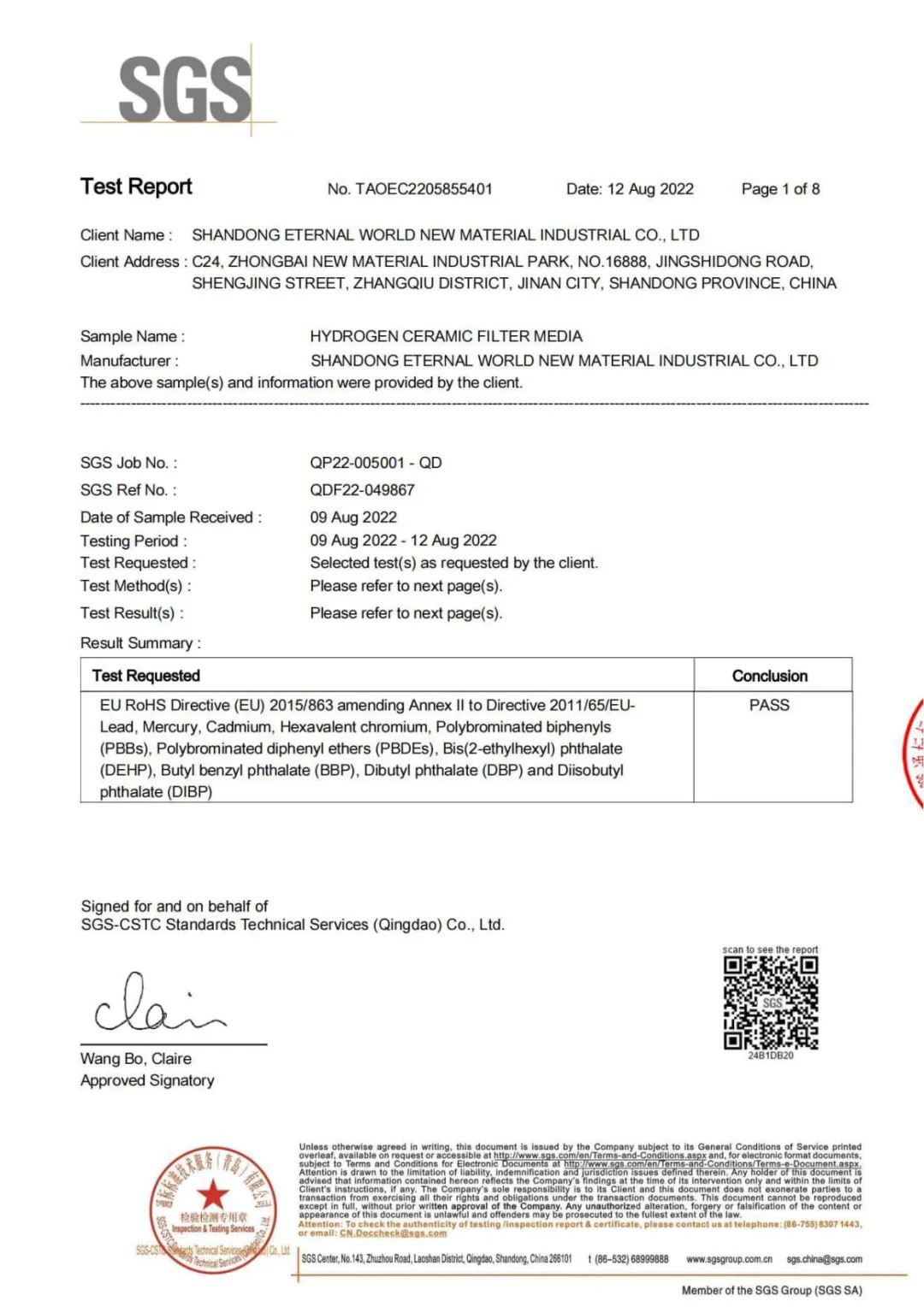

Secondly, it depends on whether the material has a test report from an authoritative third-party testing agency at home and abroad. Mineral hydrogen production materials are water-related products and need to have a safety test report that complies with the "Drinking Water Hygiene Standards". Generally, a test report from the authoritative organization SGS or exported abroad will be provided. At the same time, the test report also needs to include a test report on the dissolution of harmful elements.

Upgrading water purifiers to hydrogen ion water machines presents a new market opportunity, and choosing the right hydrogen production technology and materials is crucial for water purifier companies and brands. It's important to consider not only cost, after-sales service, and effectiveness but also consumer demand for hydrogen water.

Upgrading water purifiers to hydrogen ion water machines presents a new market opportunity, and choosing the right hydrogen production technology and materials is crucial for water purifier companies and brands. It's important to consider not only cost, after-sales service, and effectiveness but also consumer demand for hydrogen water.